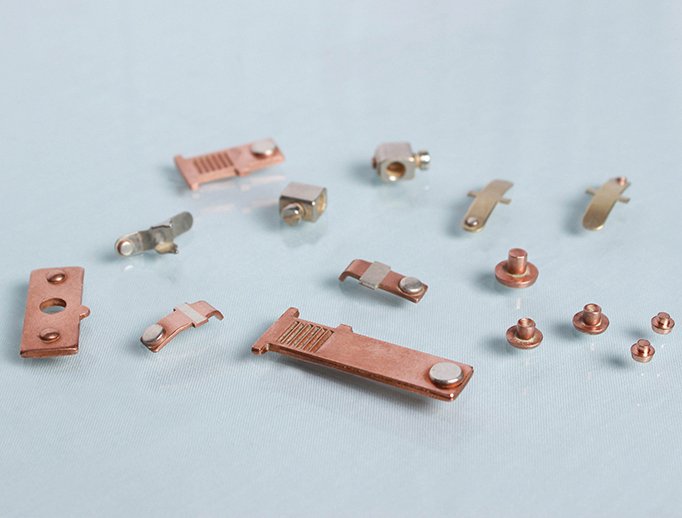

RIVETS & TIPS

Bimetal Rivets and tips

SEPL manufactures several types of bimetal rivets and tips. The rivets are usually manufactured by 'cold heading' the precious contact material typically with copper as the base material. Bimetal tips are manufactured either by cold heading or strip bonding. The contact material on the rivets could be Fine silver, silver nickel, silver cadmium oxide or silver tin oxide. Our sales team can assist you in choosing the right material for your requirement.

Solid Rivets and tips

SEPL can also supply rivets or tips in ‘solid’ metal configuration. Just like bimetal rivets, customers could choose from either Fine silver, silver nickel, silver cadmium oxide or silver tin oxide as the contact material.

Assemblies

SEPL specialises in supplying contact assemblies made by riveting a solid or bimetal rivet on to a press component or an extruded part. The riveting could be done either by 'impacting' or 'orbital' method. Our in house tool room and press shop allows us to develop various varieties and combinations of parts.

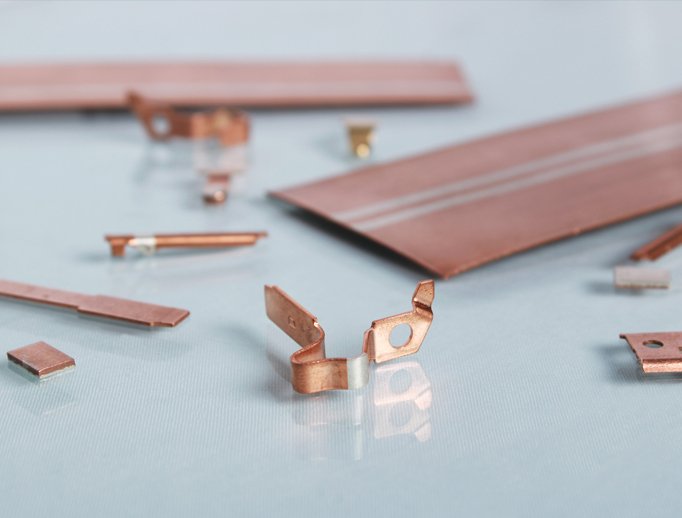

WELDED CONTACTS

Wire Welded

SEPL has in line vertical wire welding capability. This is a fast and efficient method of welding contact materials such as fine silver and silver nickel as wires onto the base metal strips such as copper and brass. Final parts are then stamped as per customer requirement.

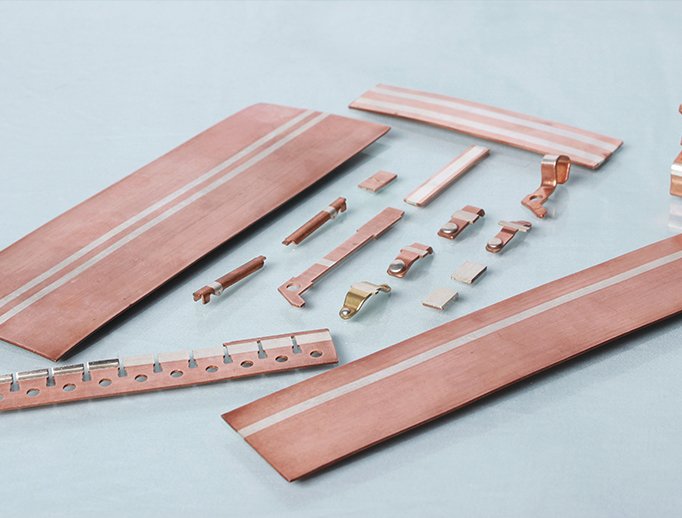

Tape Welded

SEPL has horizontal welding capability to weld various types of contact materials in the form of tapes to base materials such as copper, brass or beryllium copper. Customers can choose from solid or multilayer tapes. The welding is fast, efficient and continuous. Final parts are then stamped as per customer requirement.

Tip Welded

SEPL can also supply contact assemblies by discretely welding single tips of a wide variety of contact tips on to the carrier part (base metal substrate) directly using manual or semi automated welders. This type of welding is useful when size, shape or quantity restrictions do not allow a fully automated process to be feasible.

INLAY & OVERLAY

Inlay and overlay strip

SEPL has a world class production line to manufacture continuous strips of silver inlay or overlay using cold or hot bonding technology. These strips can be supplied with a choice of fine silver, silver nickel, silver cadmium oxide or silver tin oxide as the contact material and brass or copper as the base material.

Inlay and overlay parts

The In-house tool room and press shop at SEPL enables us to develop and supply a wide variety of inlay or overlay components.

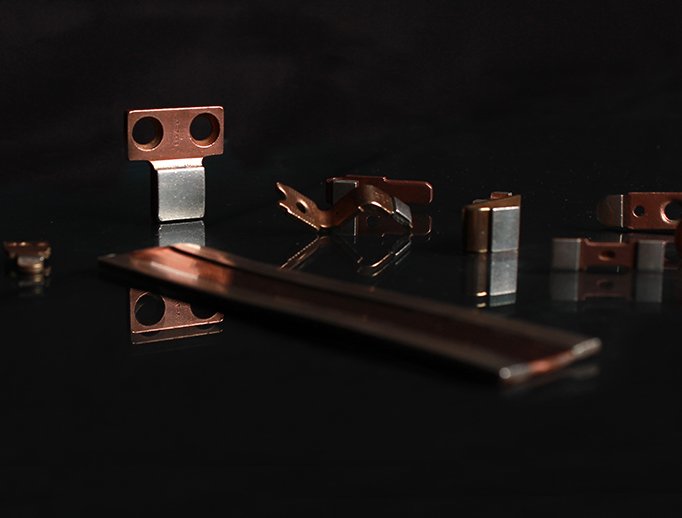

BRAZED CONTACTS

Toplay

‘Toplay’ is a continuous brazing process where strips of contact material, braze alloy tape and a base metal are fed into a die and heated in an induction chamber, the heating melts the braze alloy forming a bond between the contact material and the base material. This high speed brazing process is continuously monitored by a C-scan unit that detects voids, if any in the braze joint. The strip is then form rolled to achieve final hardness and thickness before being stamped into components as per customer requirements. Assemblies made by ‘toplay’ are typically superior in quality due to an increased braze area, a better overall bond quality and a substantially lower braze thickness.

Tip brazing

SEPL can also supply contact assemblies manufactured by discretely brazing tips on various types of carrier components. Tip brazing is useful when size, shape or quantity does not allow a continuous strip brazing process to be feasible.